Kateřina Navláčilová from NeVo attended the SMT Info seminar where she presented new trends in soldering. The topic of the presentation from Watson Tseng (Shenmao Technology Inc.) was Thermal Fatigue Resistance Lead-free Solder Paste. This very interesting presentation was focused on the PF918-P250 alloy designed for higher thermal stability.

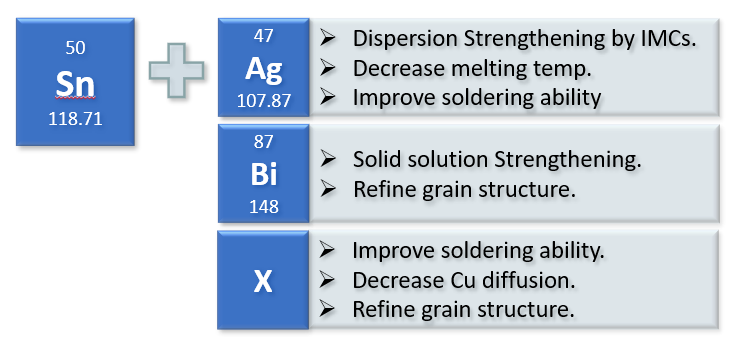

Shenmao PF918-250 SAC alloy with Sn/Ag4.0/Bi3.0 composition have increased thermal stability properties, better mechanical shock reliability and very similar melting temperature range (~220°C). PF918 alloy is also available in BGA balls form.

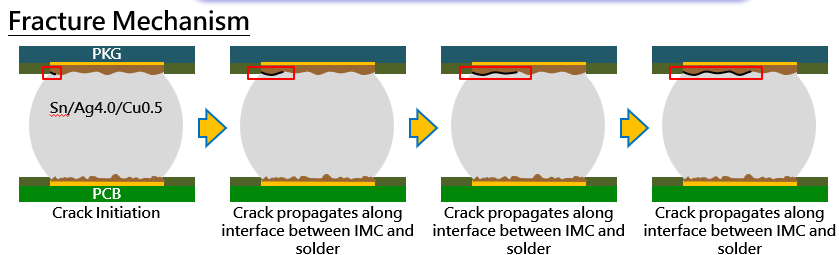

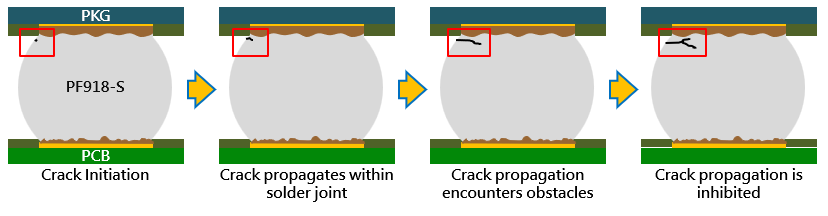

Shenmao R&D department has shown through extensive testing that compared to conventional SAC alloy, the PF918 BGA solder balls have ⅓ more cycles to first fail during thermal cycling test. This great result is achieved thanks to an inhibition mechanism during crack propagation.

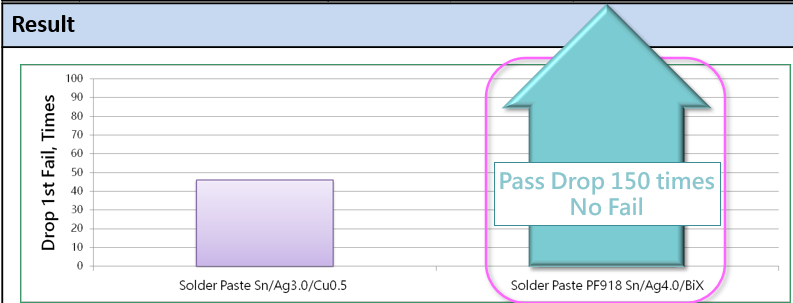

Mechanical shock tests for these BGA balls showed that PF918 has comparable results to Sn/Ag3.0/Cu0.5.

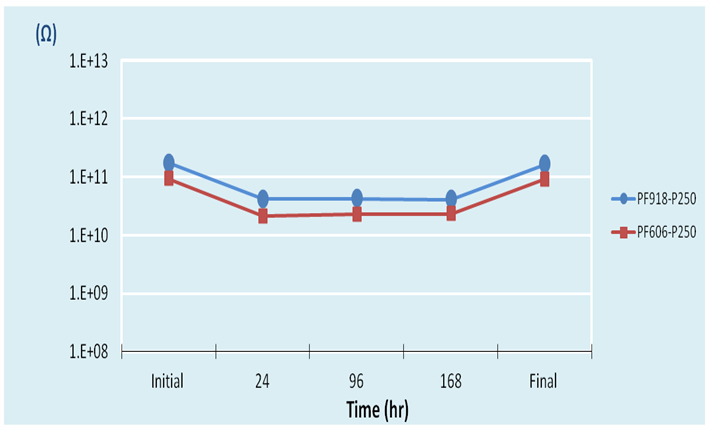

When we focus on solder paste with this specific composition PF918 Sn/Ag4.0/BiX with very good printing properties, the thermal cycling test results are comparable, but mechanical shock tests are even much better. The paste was also examined in terms of SIR and the probability of voids presence. SIR test based on IPC-TM-650 2.6.3.7 standard showed very good results.

Wide void testing proved, that void presence is lower comparable to SAC305 on air and also with using N2 (O2 < 3000 ppm) heating ambient.

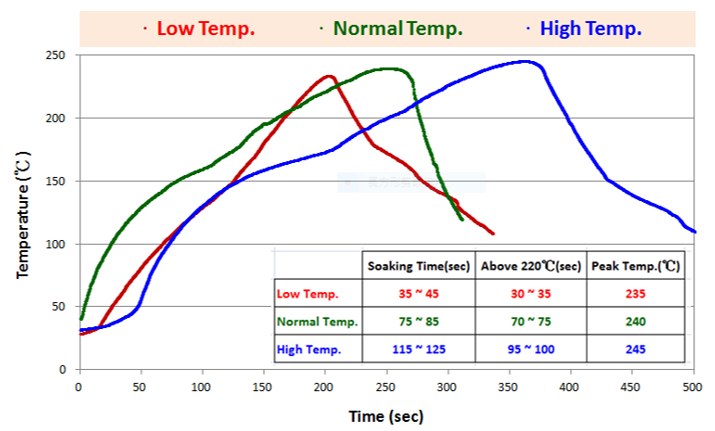

Big advantage is that PF918 has a melting temperature range comparable to SAC alloys, so it’s not necessary to change temperature reflow profiles. In many cases it is even possible to use the ones currently in use.

PF918-P250 alloy has no significant environmental impact (Sn, Ag, Bi), complies with RoHS & RoHS 2.0, compiles with REACH. No used compounds are listed in SVHC.